later post | index | earlier post

How many different types of copper are there?

Thursday, 25 May 2023

Copper is one of the most heavily used metals in the world because of its versatility, malleability and high conductivity. As it is used so frequently, it is one of the most recycled metals globally. Everyone needs copper, and there is plenty of it coming up for scrap.

In this article we look at the types of copper that are out there, and what products you might find copper in. There are as many as 400 different types of copper and copper alloy compositions, but they can be arranged into the following broad categories:

Pure Copper

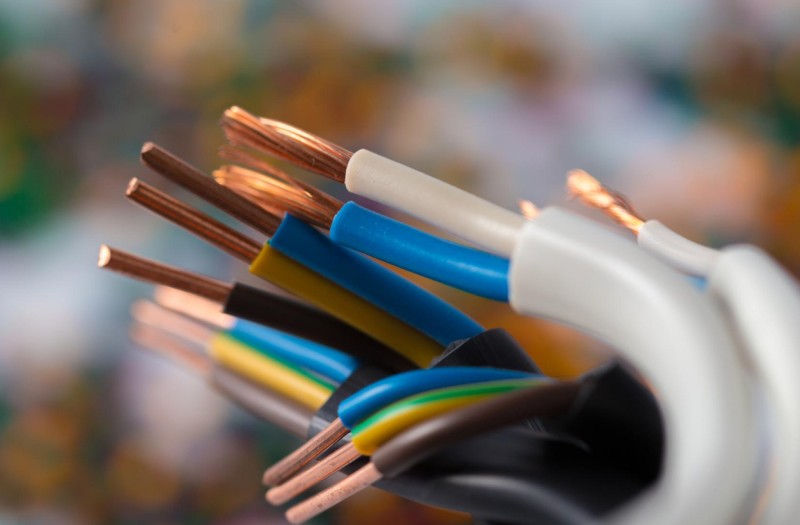

With the highest electrical conductivity of any commercial metal, pure copper is the most popular type of metal for the electrical, engineering and telecommunications industries. Pure copper contains a minimum copper content of 99.3% and can be found in all kinds of electromagnetic wire, cabling, electronic components and printed circuit boards.

These applications demand high levels of ductility, strength and hardness, and an ability to withstand temperatures of up to 100°C. This type of copper will generally be graded into ‘bare bright copper’, #1 or #2, with bare bright copper being the most valuable as scrap.

These grades of copper can be found in copper piping and copper cylinders. If ‘clean’ this can fetch some of the highest scrap metal prices. Find out more about grades of scrap copper.

High Copper Alloy

The coppers with the next highest copper content are high copper alloys. These are metals created to meet higher operational demands than pure copper (eg. hotter temperatures) but with similar levels of electrical conductivity.

Copper content in high copper alloys tends to be at least 96%. Thermal transfer properties and corrosion resistance are other characteristics of copper alloys.

Examples of high copper alloys are cadmium, beryllium, chromium and zirconium. Typical applications for high copper alloys include electrical terminals and connectors, springs for relay contacts and switchgear.

Brass

Brass is a specific type of copper-zinc alloy, rather than a separate metal. Brass is strong, machinable, conductive and corrosion resistant. It is non-magnetic, so has long been associated with clock and watchmaking, but is also good with water.

Brass is used heavily in marine engines, pump parts and water pipes. Obviously, many musical instruments are also made of brass. “Where there’s muck there’s brass”, so the saying goes.

Brass was certainly used in coinage as long ago as ancient times, but less so today. However, a brass alloy with a small quantity of nickel can be found in today’s UK pound coin. The most common types of brass we see at our metal recycling centres are brass rod borings, brass borings and brass radiators.

Bronze

Bronze is a copper alloy with tin as the main other metal. Lead and silicon are also found in some bronzes. Tin gives bronze strength and hardness, as well as having good resistance to corrosion.

Like brass, bronze reacts well to saltwater and freshwater, so is used in marine architecture such as engine parts, pumps, propellers and ship’s bells. Phosphor bronze precision-grade wire is ideal for compression springs and electrical contacts. Bronze can be machined and poured easily so is used in industrial castings like bearings, bushings, pump and valve stems.

Copper Nickels

As its name suggests, copper nickel is a copper alloy consisting of copper and nickel. Also known as cupronickel, the most common form of this alloy combines 90% copper with 10% nickel. Its good resistance to seawater corrosion makes copper nickel a favoured metal for the shipping industry.

You will also find copper nickel in offshore oil and gas production along with power generation. Heat exchangers and piping systems are common applications for copper nickel. Cupronickels with 30% nickel content are used where higher mechanical properties are needed.

Other Common Copper Alloys

Copper-nickel-zinc and leaded coppers are among the other most common types of copper alloys. Products made from a copper-nickel-zinc alloy base are silvery in appearance but not actually silver. For example, most ‘silver’ cutlery is Cu-Ni-Zn in composition.

Lead is added to copper to act as a lubricant and aid machining. Leaded coppers take the form of low lead or high lead alloys, but there is an increasing emphasis on keeping lead content as low as possible.

Sell your scrap copper to ASM Metal Recycling

ASM Metal Recycling is always ready to buy good quality scrap copper. Copper is one of the metals we recycle most, and the better grades command competitive prices. We will grade the copper we receive and use digital scales to give you the most accurate weight and value for your scrap copper. Contact us today to enquire about selling your scrap copper to ASM Metal Recycling.

later post | index | earlier post

Recent posts

- What to do with radioactive scrap metal

- How does metal recycling benefit the economy and the environment?

- 5 common metals that can be recycled

- How does metal recycling work?

- How to Sort Metal for Scrap

- How to classify the different types of waste your business produces

- What is WEEE waste?

- Can iron be recycled in the UK?

- What has the most copper in it to scrap?

- How to better understand scrap metal pricing

- Is there a link between copper and brass prices?

- How to make money from cable scrap

- How many different types of copper are there?

- What can I sell to a scrap metal yard?

- Preparing for the collection of scrap metal